AEIC also provides energy management, energy audit and energy saving solutions to our clients and with two financial plans for energy saving project:-

Mode 1: Turnkey Project

– client pays 100% for the project and gain 100% saving profit from project.

Mode 2: Financial Project

– client does not pay one cent for the project and share the saving profit from project.

Please contact us for details now and get a draft proposal. =>click here

![]() OTHER ENERGY SAVING PRODUCTS

=>go

OTHER ENERGY SAVING PRODUCTS

=>go

![]() AIR-CON SAVER => Details

AIR-CON SAVER => Details

![]() Lighting Retrofitting

Lighting Retrofitting

Lighting retrofitting can use latest and advanced technologies and products. AEIC recommends you with:-

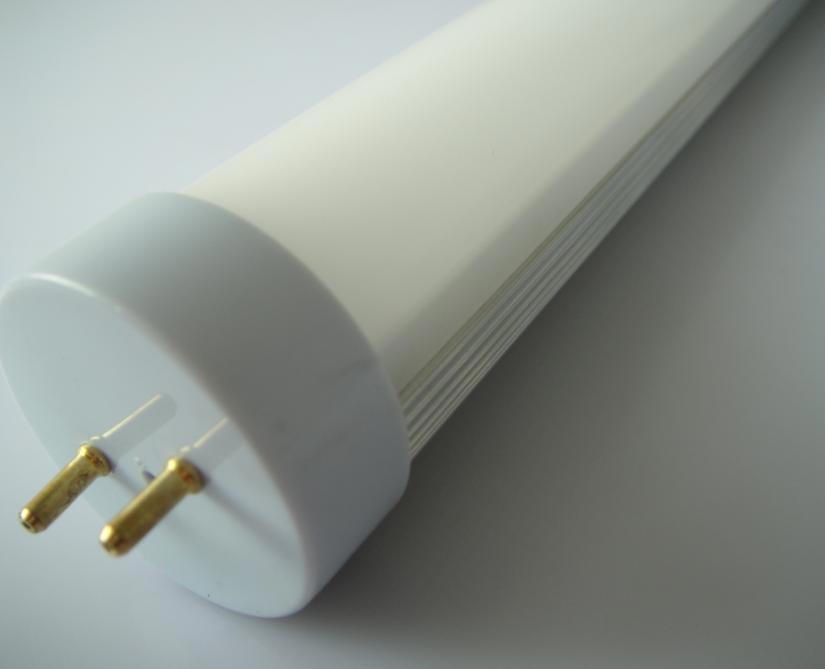

![]() LED T8 Tube to retrofit traditional

lighting system

>> on

request

LED T8 Tube to retrofit traditional

lighting system

>> on

request

![]() LED light to retrofit existing neon

light

>> on

request

LED light to retrofit existing neon

light

>> on

request

![]() Solar LED light to retrofit existing street

light

>> on

request

Solar LED light to retrofit existing street

light

>> on

request

![]() HF-EDL light to retrofit traditional HID

lighting system

HF-EDL light to retrofit traditional HID

lighting system

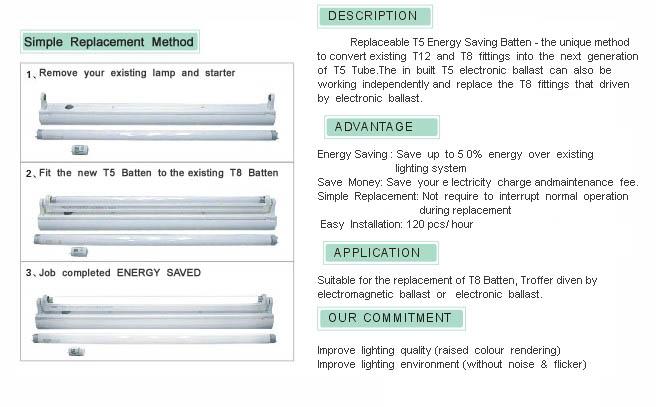

![]() T5 adaptor to retrofit traditional

T8 fluorescent lighting system

T5 adaptor to retrofit traditional

T8 fluorescent lighting system

In some instances replacing old equipment with newer, more energy efficient equipment is warranted. In many cases, local utilities will offer rebates for such upgrades and the energy savings can be dramatic. For example, inefficient older T-12 and T8 fluorescent lamps with electro-magnetic (EM) ballasts are replaced by more modern electronic ballasts with T-8 or T-5 lamps; HID, HPSL & HPM can be replaced with high efficiency lamp, such as HF-EDL. This treatment alone can cut the electric bill for the lights by 30% - 65%!

1. T5 adaptor for T8 fluorescent tube => Details

T5 adaptor applies advanced T5 technology to retrofit T8 fluorescent tube in simple way. If you are concerned for the retrofitting cost, we recommend you to replace the T8 fluorescent light with the T5 adaptor. This treatment alone can cut the electric bill for the lights by 25% to 45%!

1.1 T5 adaptor Test Result => Details

|

Testing tube |

Nominal Watts |

Running Watts* |

Running Pf |

Lux** |

|

|

Range |

Range |

||||

|

T8 Phillips |

36+ |

42 |

0.38 |

175-181 |

178 |

|

T5 adaptor |

28+ |

24 |

0.97 |

173-177 |

175 |

|

T5 adaptor to T8 |

-8+ |

-18 |

+0.59 |

(-2)-(-4) |

-3 |

|

- |

-42.86% |

+155.26% |

- |

-1.6% |

|

* Watts are

including consumptions of tub and ballast for single tube. The result will

vary with the light conditions.

** Lux is measured at 1.5 meters direct under the tube at the starting time.

1.2 T5 Adaptor Installation >>details

| T5 Adaptor |

| suit for T8 4ft tube |

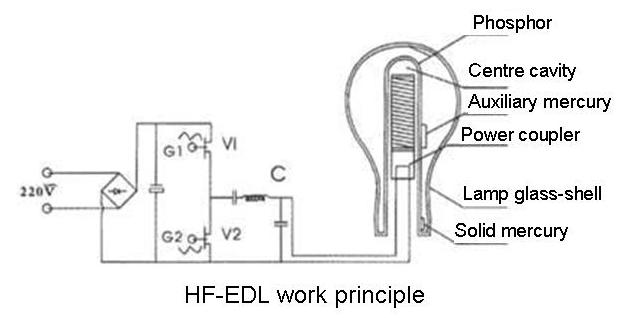

2. High Frequency Electrodeless Discharge Lamp (HF-EDL) => Details

HF-EDL applies

techniques of Electromagnetic induction and discharge of fluorescent gas to

ionize the fluorescent gas to plasma. The fluorescent powder will generate

visible light after it is stimulated by UV that is generated by stimulated

plasma.

2.1

Advantage:-

1. Long lifespan – ≥60,000 hours

2. Short start and restart time – <0.5 seconds

3. High power factor – ≥0.98

4. Low surface temperature – <90ºC

5. High Stability – Flicker free

6. Wide voltage range – 125-265V

7. High Ra – >80

8. Low maintenance fee – Mostly free maintenance in first 3 years

2.2 Advantage – Lifespan compares with HID:-

LED LIGHT applies advanced LED technology to retrofit conventional lights and lets you get electricity saving up to 60%.

4. Solar powered lighting

Solar powered lighting brightens your place with free energy.

![]() AIR-CON SAVER

AIR-CON SAVER

Application:

1.

Air-con used in house, commercial building, office, hotel and hospital, etc.

2. FCU (Fan Coil Unit is hooked up thermal sensor) used in buildings and

factories.

3. Fridge used in supermarket, hotel, restaurant and hospital, etc.

4. Ice maker used in

supermarket,

hotel, restaurant and hospital, etc.

Efficiency:

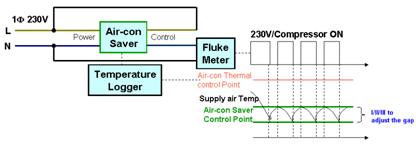

Save electricity up to 30% and vary with equipment condition. See below test trend for Nation two-system Air-con (got 26% saving while applied one Air-con Saver to one fan coil unit, another fan coil unit is running as normal). We guarantee 10% saving for non-inverter air-con.

Air-con Saver applies fuzzy-logical technology to simulate human being’s sense of temperature and enhance the refrigeration efficiency by optimizing the operation curve of compressor, as well as to control compressor to adjust cool air output and prevent the air over-cooled from over-using energy, and further to save the over-used energy. It's carried out as follows:-

1.

Save electricity thru controlling low limited temperature. According to the

operation curve of air-con compressor, when compressor runs to the low

limited temperature, the whole temperature will rise, the current and the

energy expenditure will also increase. However, the cooling temperature will

never go down any more or very less. In this situation, the Air-con Saver

will control the compressor to stop, and to save the energy that will be

wasted on. In the meanwhile, the compressor is completely cooled down, and

its reliability will be increased.![]()

2. The cooled refrigerant still maintains in the compressor system after compressor stopped. As the cooling fan continues to run while compressor stopped, the air from cooling fan still keeps cool and maintain the room temperature. When the air temperature rises to certain level, the simulator of Air-con saver will control compressor to start up for next cycle, and so on. This does avoid compressor frequently starting up, and the energy is saved successfully.

3. Avoid frequently starting up the compressor. The compressor's start and stop are controlled by protractor. In the state of heating, it stops when the temperature is higher than the targeted setting, and starts while lower. In the state of cooling, it starts when the temperature is higher than the targeted setting, and stops while lower. Actually, the work cycle is a few minutes. So frequent to start and stop compressor, it will bring in rush current impact and huge energy expenditure. Whereas the working cycle of air-con saver is scores of minutes, it avoids frequent rush current impact to compressor and extends compressor's lifespan.

Note: This saving efficiency is adjustable through a "saving selection" switch which is classified in 3 grades. When the switch is selected in different grade, the saving efficiency will be different as 20%, 25% or 30% for the air-con with middle grade of efficiency. Air-con Saver also equips a bypass switch to switch saving mode to normal operation mode.

Specification:-

Model: ACS-II (suit for less than 3HP air-con)

Supply source: 1Ф/230Vac;

Consumption: <4W;

Dimensions: 250 X 85 X 50 (LXWXH) mm³ (for two-unit package)

Weight: 0,7Kg (for two-unit package)

Model – ACS-III (suit for less than 5HP air-con); ACS-IV (suit for less than 10HP air-con and subject to special request)

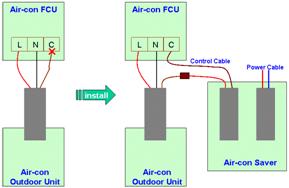

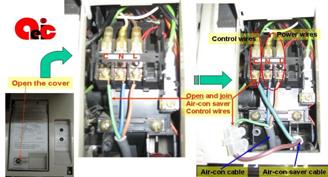

Ease of Installation as below instruction:-

Power Saver equips a Digital Signal Processor with patented software of energy management and control which senses the current and voltage and precisely control power output, and let the power output match with the load request. This can save your money on the operation of the induction loads through reducing electricity wastage by:

√

Improving the induction

load efficiency.

√

Modulating the power

output according to the loading.

New

developed Power Saver shall monitor motor working condition through linked

PC or network, log all motor parameters for analysis or for preventive

maintenance.

Tell us what you need, we will provide you a proposal.

>> Power Saver's Benefits for Users

>> Wiring diagram for integration

![]() Power Saver

Power Saver

Power Saver equips a Digital Signal Processor with patented software of energy management and control which senses the current and voltage and precisely control power output, and let the power output match with the load request. This can save your money on the operation of the induction loads through reducing electricity wastage by:

√

Improving the induction

load efficiency.

√

Modulating the power

output according to the loading.

Power Saver provides additional and valuable solution on Energy Saving for the devices which results can not meet your requirement, and lets you get saving up to 40%. The results have been tested by the Authorities, Labs and Clients.

Testing Results for Refrigerator and Air-conditioner

Typical Application and Saving

Input

Voltage: 90Vac

– 240Vac (Single phase); 240Vac – 480Vac (3-phase)

Input

Current: 10Amps

– 200Amps (Single Phase); 20Amps – 2000Amps (3-phase)

Frequency: 50 or 60Hz with auto detection and switching

Output

Voltage: 90Vac – 240Vac suitable for single phase

240Vac – 480Vac suitable for

3-phase

Output

Current: 10Amps

– 200Amps (Single Phase); 20Amps – 250Amps (3-phase)

above 250Amps devices need special order.

Soft

Start Ramp up Time: 1 to 60 seconds, adjustable

Soft

Stop Ramp down Time: 1 second fixed, option on 1 to 60 seconds, adjustable

Correction

Factor: Manual or Automatic

Delay

to On: 1 to 60 seconds, adjustable

Delay

to Save: 5 to 60 seconds, adjustable

Transient

Voltage Protection: Yes

Over

Current Protection: Yes

Short

Circuit Protection: Yes

Remote

Start/Stop: Yes

Fail-safe

Bypass: Yes

Power

Surge Protection: Yes

Thermal

protection: Temperature sensor on Power Unit

Weatherproof: NEMA3. On request for NEMA12.

:

Power

Saver’s Benefits for Users:

“Immediately

save energy and money after starting to use POWER SAVER”

√ Quick

Payback – less

than 3 years, typically at 15

months period based on electricity

savings alone.

√ Return on Investment (ROI) – mostly more than 30%.

√ Direct

Savings (tangible)

–

Reduce

the electrical demand and consumption.

√ Indirect

Savings (Intangible)

Extend

the lifespan of electric equipment

(e.g. motor) by reducing:

§

The

operating temperature – cooler running

§

The

internal friction of bearing

§

The

noise and vibration

Reduce

maintenance cost

§ Reduce equipment breakdown and save repair costs

§

Reduce troubleshooting time and cost through PC interface software

Increase

motor efficiency and reliability

§

Soft

start / stop

§

Improve

the power factor

§

Balance

the voltage between phases

§ Motor parameters logging for preventive maintenance or troubleshooting

![]() OTHER ENERGY SAVING PRODUCTS/SOLUTIONS

OTHER ENERGY SAVING PRODUCTS/SOLUTIONS

The PowerSaver is a product with almost universal application, used to reduce the energy consumption and improve power quality on all types of AC motors (machinery, air conditioning, refrigeration, etc.). It does this by cancelling a portion of the power normally drawn by these loads. And, more importantly, it does so without negatively affecting horsepower, speed, or reliability.

The PowerSaver reduces the wasted energy normally used by these motors by aligning the phase angle of the supplied voltage and current. This saves energy, reduces heat generation inside motors, frees up new electrical capacity within a facility, and produces a net kilowatt hour reduction on an electricity bill.

PowerSaver benefits to user:

![]() Increases

electrical capacity

Increases

electrical capacity

![]() Lowers KW

consumption and demand

Lowers KW

consumption and demand

![]() Eliminates

power factor penalties

Eliminates

power factor penalties

![]() Improves

facility voltage

Improves

facility voltage

![]() Cools

overheated lines and panels

Cools

overheated lines and panels

![]() Improves

facility power factor

Improves

facility power factor

![]() Lasts for

140,000 hours of service

Lasts for

140,000 hours of service

![]() Extends the

life of motors

Extends the

life of motors

Motor Controllers

Motor controllers can be used in conjunction with capacitors or as stand alone treatments. If your company uses electric motors you can profit from installing motor controllers. Although motors play a vital role in industry there are major inefficiencies in their operation that causes motors to be 70% of the electric cost for many industrial facilities. As amazing as it seems a motor can consume 20 times of its cost each year in electricity!

A large amount of electricity is wasted when motors are not operating at full load. Most motors operate at less than full load 75% of the time! Motor controllers utilize powerful microprocessors to ensure that the motor gets exactly the correct amount of power it needs to perform the job at hand, thus saving substantial amounts of electricity. Even slight changes in demand will be perceived by the motor controller with an instantaneous response for maximum operational efficiency. The motor controller will precisely match the power input to the load requirements.

Another problem addressed by motor controllers is the high torque developed when AC induction motors first start up. The acceleration torque is substantially greater than what is required by the motor when running under full load. The stress is spread throughout many important components of the motor such as the transmission system causing excessive wear and higher maintenance costs. The high inrush currents also have a huge effect on the electrical supply charges with start-up currents often times 8-10 times higher than normal operating currents.

Motor controllers recommended by us will provide an economical and reliable solution to the built in inefficiencies of AC motors. The motor controller will implement a controlled release of power to the motor, providing smooth, stepless acceleration and deceleration.

The LightSaver Power Savings System

The LightSaver are not applicable in every situation. But when called for they will effectively reduce the watts consumed in treated lights by 10% - 40%. The LightSaver fools the light by modifying the sine wave. By cutting out the leading edges the controller effectively continues to give the light the voltage it needs but using less watts in the process.

The LightSaver can work with all type of lighting systems including fluorescent, incandescent, and all types of HID including, Sodium, Metal Halide, and Mercury Vapour. The LightSaver can interface with dedicated lighting circuits in voltages of 120, 277, 240 or 347 and amperages up to 20 amps per circuit.

Refrigeration & Air Conditioning Oil Additives

One of the simplest yet most effective treatments we may recommend is the addition of special patented, halogenated hydrocarbon additives to refrigeration and air conditioning systems, including chillers and heat pumps. Proven in hundreds of installations during the last 15 years, these special additives reduce friction on moving parts giving new life to bearings, seals and compressor parts. Reducing the friction in the system improves the compressors mechanical efficiency and lowers electrical consumption. You will immediately notice increased cooling capacity and a quieter compressor. Best of all, you'll notice the savings on your electric bill. This treatment alone can save 10-15% on the electric use of the treated system.

Air Conditioning Controllers

The patented controller works on any air conditioning unit with a hermetically sealed compressor, even anything from a window unit to a 10 ton unit and larger. A smart logic circuit in the controller maintains the air conditioner at maximum efficiency. Unlike alternative air conditioner controllers that are time or movement activated, the controller has a dew point sensor installed adjacent to the condenser that turns the air conditioner off once the dew point has been reached. This is the most exact way to insure no electricity is wasted because air will not be cooled beyond the dew point even if the air conditioner is operating on maximum cold and full blower fan. Alternative types of controllers fall short of achieving maximum savings because their arbitrary shutoff criteria still allows the air conditioner to be running past the point that it is possible to continue cooling the air. We recommended air conditioning controllers typically save 15-25% on the air conditioning portion of the electric bill.

Refrigeration Enhancement Systems

Another treatment often recommended by us either as a stand alone or in conjunction with other treatments, utilizes a vortex through a fixed impeller to reduce the load on the compressor. The device is an add-on for air cooled condensers. It not only increases the cooling efficiency of the unit but also reduces the pressure in the system, reducing energy cost and extending the productive life of refrigeration system compressors, saving additional money on maintenance and parts replacement.

Vending Machine Controllers

Although you generally would not think of vending machines as large electricity consumers, they are on 24/7 and over a year can run up a significant bill. In low to medium traffic areas, we will recommend infrared activated controllers for cold vending machines. Endorsed by over 100 Utility companies and installed at over 100 Universities and schools, these controllers save an average of 46% on the cost of running a vending machine while still maintaining the usual and expected cold temperature for the dispensed soft drinks and juices.

Daylighting Sensors

Many rooms with south facing windows have more than adequate light during the day on most days, provided free by the sun. In such rooms an inexpensive, fast payback treatment is the installation of Daylight Sensors that keep lights off when ambient light is sufficient and automatically turn the lights on during working hours if natural daylight light levels fall below a specified threshold.

Occupancy Sensors

Many rooms are frequently unoccupied with lights or other equipment inadvertently left on even when the room is empty. During our Site Survey we will note rooms with infrequent use such as lunch rooms and recommend Occupancy Sensors. The sensors will power down or turn lights and equipment off when the room is unoccupied and bring things back to full power as soon as someone enters the room.

Transient Voltage Surge Suppression (TVSS)

TVSS systems primary purpose is to protect valuable equipment from harmful energy spikes. Many TVSS products offer little or no energy savings as they have high spike tolerances and are infrequently activated. However TVSS products that operate on low spike tolerance keep voltage in check continually and can cut a facilities electric bill substantially while also protecting critical and sensitive equipment such as:

![]() Computer

Systems

Computer

Systems

![]() Variable

Frequency Drives

Variable

Frequency Drives

![]() Fluorescent

Lighting and Ballasts

Fluorescent

Lighting and Ballasts

![]() Solid State

Transmitters

Solid State

Transmitters

![]() R.F.

Equipment

R.F.

Equipment

![]() Irrigation

Systems

Irrigation

Systems

![]() Medical

Equipment

Medical

Equipment

![]() HVAC

Systems

HVAC

Systems

![]() Audiovisual

Equipment

Audiovisual

Equipment

![]() Security

Systems

Security

Systems

![]() All

Electrical Equipment

All

Electrical Equipment

Transients and power surges can come from the utility grid as well as from inside your electrical system. Small surges can occur multiple times a day to thousands of times per hour, ranging from several thousand volts to under 100 volts. Activities by your Utility company such as switching can also cause powerful surges which may be carried along utility lines. When the surge reaches your facility it may still have enough energy to jump across switches, even those which are turned off, and damage your electrical equipment.

Power surges can also be generated by your equipment within the facility and some of the equipment actually destroy themselves from the transient surges and voltage fluctuations they create. Harmful surges can be caused by:

![]() Elevators

Elevators

![]() Pumps

Pumps

![]() Office

Machines

Office

Machines

![]() HVAC

Equipment

HVAC

Equipment

![]() Electric

Motors

Electric

Motors

![]() Emergency

Supply Transfer Switches

Emergency

Supply Transfer Switches

You can greatly increase the operating efficiency and life of your equipment and provide local, decentralized power conditioning for your critical equipment by installing TVSS at the equipment's energy source. Icing on the cake is that you can also save electricity. Maximum protection can be gained for your heavy duty equipment by installing TVSS at the main electrical panel and sub-panels for this equipment.

Active Harmonic Filters

These are electronic devices which can be suitably installed at selected points in a building or industrial plant electrical distribution system which will approximately cancel harmonics. Harmonics are normally caused by loads such as printers, computers, variable speed drives, MRI units, and other nonlinear operational devices. In some cases the harmonics can lead to large circulating currents, reduced transformer and electric cable capacity for normal loads, and the cause of nuisance breaker trippings. In extreme cases, harmonics can burn up the neutral of power distribution systems, leading to unscheduled outages of power. Energy cost savings can vary substantially, depending on the level of harmonics, which must be measured; KWH savings can vary from 1-2% up to 10-15% in extreme situation.

Sales Enquiries,

Technical Support at

[email protected]

Copyright 2003 - 2013 © www.aeics.com.

Best viewed with Internet Explorer 6.0, 800x600 resolution.